Joshua Daugherty, M.S.

Mechanical Engineer

Mechanical Engineer

Project with Lochinvar to design a more effective heat exchanger

Fire boiler tubes are tubes that hold extremely hot post-combustion gasses and allow transfer heat energy to pass into a different closed system, usually water. In layman’s terms, they allow very hot gas to heat water, without contaminating the water. These tubes can come with a wide heat rating range, as well as in a wide range of efficiencies.

Fire boiler tubes are tubes that hold extremely hot post-combustion gasses and allow transfer heat energy to pass into a different closed system, usually water. In layman’s terms, they allow very hot gas to heat water, without contaminating the water. These tubes can come with a wide heat rating range, as well as in a wide range of efficiencies.

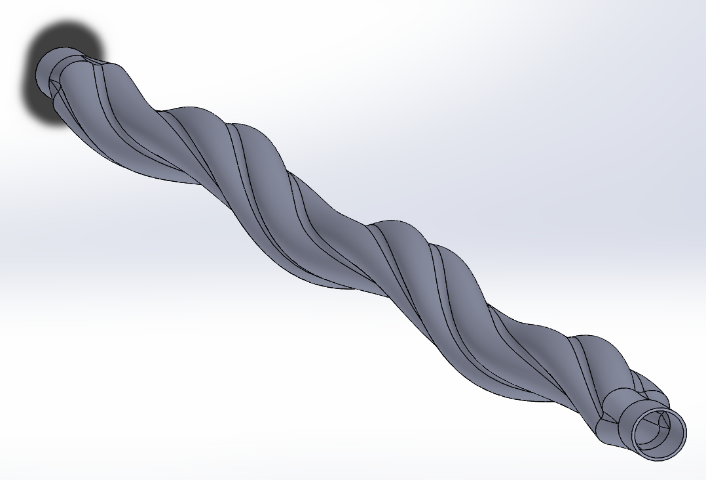

The goal of this project is to model and produce boiler tubes with different and unintuitive tube geometries, and then compare heat transfer effectivity and head loss with current tube models.

After several iterations of modeling and testing, the data consistantly showed that the core of the air column would stay warmer then the rest of the air. It was determined that this warm column would cause a drop in the net effectiveness of the transfer tube.

To assist in pushing warm air to the transfer surface, a core insert was added to the model. The benefit of a core insert, is that it would be able to decrease downstream temperature in a more uniform manner, while adding the smallest amount of headloss possible.

The first prototype should be produced in the next few weeks, which will allow us to start running live simulations and will give us concrete feedback on the results.

Currently the only products to test edema are very expensive and they are difficult to use. For this reason, many nurses when testing for edema use simpler methods that are less accurate or less repeatable. A common test is to create a dimple in the affected area and then measure the depth or the refill time of the dimple.

Our goal value proposition for this product is to combine the reliable and repeatable results of the more expensive products while offering the speed and simplicity needed to be utilized in a nurse’s hectic environment.

Our goal value proposition for this product is to combine the reliable and repeatable results of the more expensive products while offering the speed and simplicity needed to be utilized in a nurse’s hectic environment.

Our current prototype is powered by a standard spring. This offers consistent pressure when creating a dimple, which takes the human inaccuracy out of the testing. It also has an analog readout for more detailed results. Also due to the size and simplicity it will have a manufacturing cost similar to that of a pen, which if need be can make it disposable.

Our process for product integration involves getting our product approved by teacher at TTU as a requirement for nursing classes, as a training device. This will offer confidence to beginning nurses as they learn to test for edema on their own. As we build notoriety and familiarity, we can increase supply to nearby clinics and eventually to home use for self-diagnostics.

In an air compressor, the outgoing compressed air, can often be extremally hot, often in excess of 500°F. This is because of a thermodynamic property called heat of compression. The change in heat can be accounted for with a polytropic equation for air.

This equation can be solved for temperature with some creative arithmetic and the compressed outlet temperature can be calculated as following:

From this equation the inlet and outlet air streams can be compared which results in a final form of the equation for the outlet temperature shown as:

The units in this equation must be an absolute temperature and absolute pressure. A reasonable estimation for the compressor will be inlet air of 80°F and an outlet pressure of 100 psig. These values will produce the following equation:

Since I was in diapers, I have been inexaustibly curious. In school it got me in a bit of trouble because I was one of those kids who found it hard to focus on anything because everything is too interesting. I proudly still have the same curious kid inside, but don't worry; I hardly ever wear diapers anymore.

I was born in Nashville, the home of country music, where by city law, I was forced to learn to play the guitar. Occasionally I still strum a blues cord, but like all naughty children, I eventually turned down the path of rock & roll.

By the time I reached high school I started to get a grasp on what my true strength were, and began to sharpen and perfect those qualities. Those qualities were my creativity to problem solving, spatial reasoning and my thirst for understanding. This resulted in several creative projects including; a small working forge, a hydrogen generator built out of stainless-steel spatulas, and many, many spaghetti bridges. While I did not know what I wanted to do, I knew what I liked to do. This eventually led me to college to major in mechanical Engineering.

During graduate school, I was also able to join the Tennessee Tech, SEDS (Students for the Exploration and Development of Space) club. For the three years I was part of the club, I participate in several of the club rocket projects, and for the final year I was elected to be the club president. During the year, we designed several public events, and even got Joe Barnard from BPS Space to come give a presentation. At the end of the year, we released our Latest and longest-lived weather balloon, which traveled 500 miles over 19 hours to land in Oxford, North Carolina.